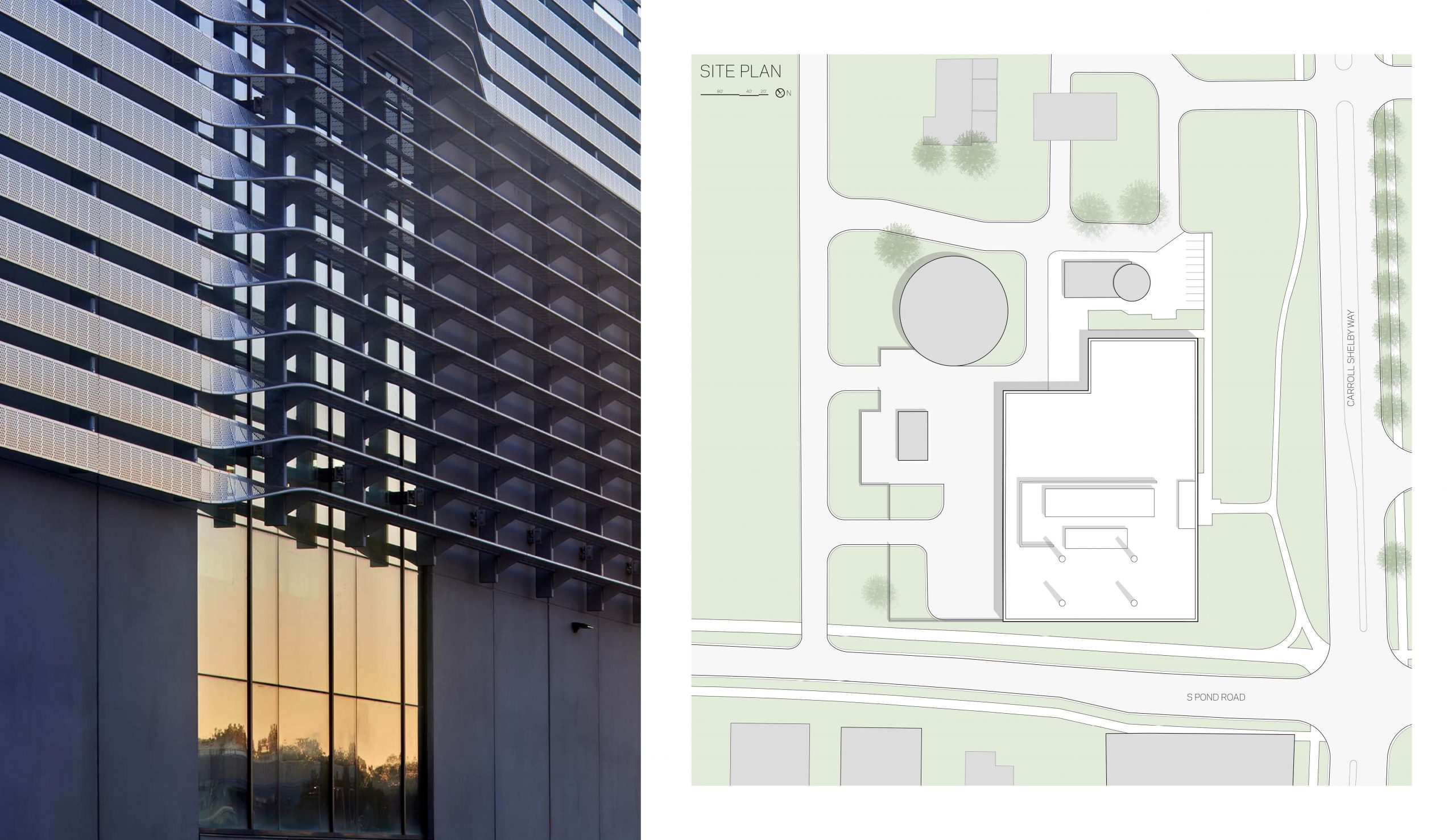

DTE Dearborn Central Energy Plant

-

ClientDTE

-

SQ. FT.118,937

-

Budget$12,000,000

-

Market

-

Year2020

- 2024 · American Institution of ArchitectsHonor Award, Iowa Chapter

- 2020 · Engineering Society of DetroitHonorable Mention, Construction & Design Award

- 2020 · Power MagazineTop Gas Plant of 2020

- 2020 · U.S. Department of EnergyBetter Plants: Better Project Winner

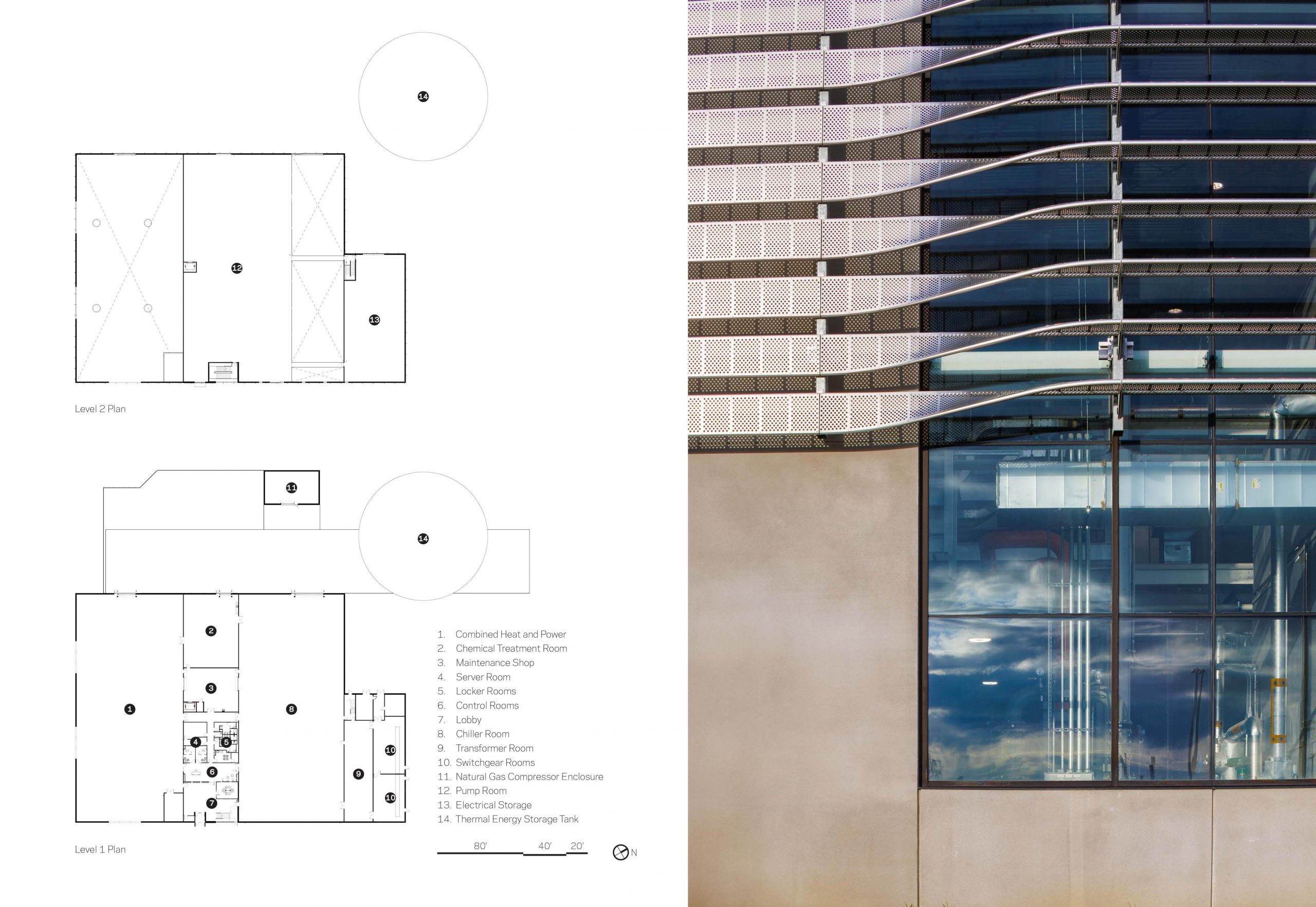

This new Central Energy Plant is at the core of a 10-year master plan to overhaul and modernize a major automotive manufacturer’s research and engineering campus. The new facility fulfilled multiple initiatives: the replacement of an aging central steam system, distributed cooling assets with a 3,000 ton geothermal system, a 19,000 ton chilled water system, as well as low-temperature water-based energy distribution loops, 40,000 ton-hours of thermal energy storage, and on-site electrical generation via combined heat and power.

The design team used the latest in three-dimensional modeling software to navigate the complex web of MEP systems to balance space utilization, efficiency, and system requirements. In addition to using clash detection and virtual design coordination on the interior mechanical areas, a combination of traditional analog methods such as sketching, paper models and three-dimensional physical modeling influenced the façade of the building. The series of ‘twisted’ blades were developed to clad what would typically be a mundane precast building, with the goal of differentiating the heartbeat of the campus and highlighting the systems that allow it to operate. Large windows also punctuate the precast, highlight systems, and let in natural light providing a healthier environment for a controls crew that works 24/7, 365 days a year.

The façade responds by ‘louvering’ open to shade the curtain wall, thus providing thermal comfort for the occupants while creating visual movement at the exterior elevations from all vantage points. The façade system required rounds of iteration, calculation, computation, and several mock-ups working closely with

fabricators to develop. It pushes the boundaries of what metal can do as well as what industrial buildings can be within a design context.

The end result is a highly efficient and flexible central energy plant that exceeds the company’s high performance sustainability objectives and pushes the envelope of modern distributed gas.